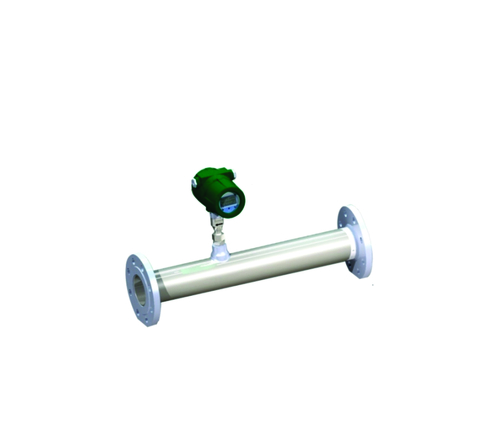

Thermal Mass Gas Flow Meter

Price 1.0 INR/ Number

Thermal Mass Gas Flow Meter Specification

- Frequency

- Optional pulse output

- Pressure Range

- Up to 1.6 MPa

- Current Range

- 4-20 mA output

- Temperature Range

- -20C to +60C

- Connectivity Type

- 4-20mA, RS485 Modbus

- Humidity %

- 0-95% RH (non-condensing)

- Measurement Range

- Various, depending on model and process conditions

- Resolution

- 0.01 Nm/h

- Flow Rate

- 0.1 to 30 Nm/h (consult model for wider ranges)

- Capacity

- Up to 30 Nm/h standard

- Sensor Type

- Thermal Mass Flow Sensor

- Material

- Stainless Steel

- Power Supply

- 24 V DC

- Power Consumption

- <15 W

- Accuracy

- 1.5% of reading

- Display Type

- LCD Digital Display

- Range

- 0-30 Nm/h (standard) or customizable

- Body Finish

- Electropolished

- Applicable Gases

- Air, Nitrogen, Oxygen, Biogas, Natural Gas, etc.

- Response Time

- 1 second

- Installation Environment

- Indoor/Outdoor Suitable

- Ingress Protection

- IP65

- Pipe Size Compatibility

- DN15~DN200 (customizable)

- Calibration

- NIST Traceable

- Output Signal

- 4~20 mA, Pulse, RS485 Modbus

- Mounting Type

- Inline or Insertion

- Power Connection

- 2-wire/3-wire

About Thermal Mass Gas Flow Meter

Theory:

The meter contains two platinum resistance temperature sensors. The thermal principle operates by

monitoring the cooling effect of a gas stream as it passes over a heated sensor. Gas flowing through

the sensing section passes over two sensors one of which is used conventionally as a temperature sensor,

whilst the other is used as a heater. The temperature sensor monitors the actual process values whilst the

heater is maintained at a constant differential temperature above this by varying the power consumed by

the sensor. The greater the gas velocity, the greater the cooling effect and power required to maintain the

differential temperature. The measured heater power is therefore a measure of the gas mass flow rate

Feature :

- Measuring the mass flow or volume flow of gas

- Do not need to do temperature and pressure compensation in principle with accurate measurement

and easy operation.

- Wide range: 0.5Nm/s100Nm/s for gas. The meter also can be used for gas leak detection

- Good vibration resistance and long service life. No moving parts and pressure sensor in transducer,

no vibration influence on the measurement accuracy

- E asy installation and maintenance.

- D igital design, high accuracy and stability.

- Configuring with RS485 interface to realize factory automation and integration

Rugged & Accurate Flow Measurement

Designed for precision, the meter delivers reliable readings for diverse gases, thanks to its advanced thermal mass sensor and calibration traceable to NIST. It operates with an impressive accuracy of 1.5% and a resolution of 0.01 Nm/h, making it ideal for a variety of process applications where measurement confidence is essential.

Versatile Installation & Connectivity

Supporting both inline and insertion mounting, this device accommodates pipes ranging from DN15 to DN200 and is customizable to suit different environments. The output flexibility420 mA, pulse, and RS485 Modbusensures seamless integration with control and monitoring systems, suitable for indoor or outdoor use.

Built for Indian Industry

Compliant with demanding industrial standards, the flow meter features a 24 V DC power supply, low consumption (<15 W), and a stainless steel body, ensuring longevity in harsh conditions. It is widely used by exporters, manufacturers, suppliers, and service providers across India seeking robust and precise gas measurement solutions.

FAQs of Thermal Mass Gas Flow Meter:

Q: How does the thermal mass gas flow meter ensure measurement accuracy across different gases?

A: This meter uses a highly sensitive thermal mass sensor with NIST traceable calibration to maintain accuracy of 1.5% for a range of gases, such as air, nitrogen, oxygen, natural gas, and biogas. Its advanced sensing technology automatically compensates for temperature and pressure variations, ensuring precise readings under diverse process conditions.Q: What is the recommended process for installing the flow meter in indoor or outdoor environments?

A: The device can be installed inline or via insertion, depending on the pipeline size and application. With IP65 ingress protection and an electropolished stainless steel body, it is suitable for both indoor and outdoor setups. The installation should follow the manufacturers guidelines for orientation and position to maintain accuracy and durability.Q: When should I select the output signal type (420 mA, pulse, RS485 Modbus) for my application?

A: Choose the output type based on your monitoring or control system requirements: 420 mA is ideal for analog integration, pulse output for totalizing flow, and RS485 Modbus for digital communication in automated or remote monitoring setups. Selection is typically decided during system design or procurement.Q: What range of pipe sizes does the meter support and can it be customized?

A: The meter is compatible with pipes ranging from DN15 up to DN200 as standard. For applications outside this range, customization options are available to suit specific requirements and process conditions.Q: How does the LCD digital display enhance usage and maintenance?

A: The LCD digital display offers real-time visibility of flow data and device status, facilitating quick configuration and diagnostics on-site. This feature simplifies operation and aids in prompt maintenance or troubleshooting, ensuring maximum uptime.Q: Where is this meter commonly used, and what industries benefit from its features?

A: This flow meter is commonly deployed in chemical, pharmaceutical, manufacturing, energy, and environmental sectors throughout India. Its versatility and robust design make it valuable for exporters, importers, manufacturers, service providers, and suppliers handling accurate gas flow measurement under varying environmental conditions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Flow Meters Category

Insertion Flow Meter

Price 1.0 INR / Piece

Minimum Order Quantity : 1 Piece

Material : SS304 / SS316 / ABS

Display Type : Other, LCD Digital Display

Oval Gear Flow Meter

Price 1.0 INR / Piece

Minimum Order Quantity : 1 Piece

Material : MS

Usage : Industrial

Color : Black

Turbine Flow Meters

Price 1.0 INR / Piece

Minimum Order Quantity : 1 Piece

Material : SS

Usage : Industrial

Color : Silver

Display Type : Digital Only

Vortex Flow Meter

Price 1.0 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Cast Iron

Usage : Industrial

Color : Silver And Black

Display Type : Digital Only

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS