Mineral Insulated Rtd Sensor

Price 1.0 INR/ Number

Mineral Insulated Rtd Sensor Specification

- Measurement Range

- -200C to +600C

- Response Time

- <5 seconds (in liquid media)

- Sensitivity

- 0.385 /C for Pt100

- Sensor Type

- RTD (Resistance Temperature Detector)

- Cable Length

- 1 meter standard; customizable

- Operating Temperature

- -50C to +550C (standard); up to 650C (special types)

- IP Rating

- IP65/IP67 (typical for mineral insulated sensors)

- Features

- Flexible, shock resistant, quick response, long service life

- Application

- Process industries, HVAC, Petrochemical, Power plants, Pharmaceutical

- Power Consumption

- Low (negligible for RTD element, typically <10 mW)

- Interface

- 2-wire, 3-wire or 4-wire connection

- Mounting Type

- Fixed (Compression fitting) or adjustable

- Wireless

- No

- Signal Type

- Analog (resistance)

- Product Type

- Mineral Insulated RTD Sensor

- Material

- Stainless Steel

- Input

- Resistance (RTD)

- Output

- Resistance (Pt100, 100 Ohm at 0C)

- Function

- Temperature Sensing

- Usage

- Industrial Temperature Measurement

- Accuracy

- Class A / B (as per IEC 60751)

- Resolution

- 0.1C

- Voltage

- Dependent on transmitter (typically 24V DC, if used)

- Weight

- Approx. 50-150g (varies with length and sheath diameter)

- Sheath Length

- Customizable as per application

- Moisture Resistance

- Good (hermetically sealed construction)

- Lead Wire Insulation

- Teflon (PTFE), Fiberglass, Silicon

- Sheath Diameter

- 3mm, 4mm, 6mm, 8mm, custom sizes available

- Element Construction

- Single or Double Pt100 element

- Sheath Material

- SS316/SS304/Inconel

- Calibration Standard

- As per IEC 60751 / DIN EN 60751

- Vibration Resistance

- High (suitable for harsh conditions)

- Termination

- Tail leads, Terminal head, Plug/socket, as required

- Customization

- Available for length, diameter, connection type

About Mineral Insulated Rtd Sensor

Product description:

Measuring Range : -50 to 400C Element Pt-100, 3-wire

Accuracy : Class A

Insulation : MI, Compacted MgO

Sheath material : SS316

Sheath Diameter : 6mm

Sheath length : 300mm

Termination W.P : die-cast aluminum head with threaded cap & chain, single cable entry

Precision Engineered For Demanding Applications

Our Mineral Insulated RTD Sensors are designed to deliver dependable and precise temperature measurement even under the most rigorous industrial conditions. Robust construction using stainless steel or Inconel, together with flexible sheath lengths and diameters, makes these sensors suitable for installation in environments prone to vibration, moisture, and temperature extremes. Tailor-made for your process, they ensure operational continuity and trustworthy results.

Superior Versatility and Customization

Choose between single or double Pt100 elements, multiple sheath diameters, and customizable lead insulation and termination options. This adaptability makes these sensors fit seamlessly into new setups or retrofits, accommodating varying process requirements. Their ability to be tailored for length, diameter, wire configuration, and output ensures you receive a solution optimized for your specific industrial scenario.

Reliable, Standards-Compliant Performance

Built to meet IEC 60751 and DIN EN 60751 calibration standards, these sensors deliver Class A/B accuracy, broad operating and measurement ranges, and high IP ratings for dust and moisture protection. Hermetically sealed construction enhances moisture resistance, supporting worry-free operation in challenging environments and over extended periods.

FAQ's of Mineral Insulated Rtd Sensor:

Q: How does a Mineral Insulated RTD Sensor function in industrial temperature measurement?

A: A Mineral Insulated RTD Sensor operates by measuring the resistance of its Pt100 element, which changes predictably with temperature. It delivers accurate temperature readings across a range from -200C to +600C, supporting industrial applications where precise monitoring is crucial.Q: What customization options are available for sheath diameter, length, and termination?

A: These sensors can be tailored for sheath diameters (3mm, 4mm, 6mm, 8mm, or custom sizes), sheath lengths to fit your application, and terminations such as tail leads, terminal heads, or plug/socket connections. Custom cable lengths and mounting types are also available to fit unique installation requirements.Q: When should I use a mineral insulated RTD over standard RTDs?

A: Mineral insulated RTDs are recommended for environments requiring enhanced vibration, shock, and moisture resistance, such as process plants, petrochemical, HVAC, and power generation. Their flexible, durable construction makes them ideal for harsh settings and dynamic temperature applications.Q: Where are these RTD sensors commonly installed?

A: These RTDs find application in industrial settings like chemical processing, pharmaceutical manufacturing, power plants, and HVAC systems-anywhere resilient, accurate, and rapid temperature sensing is necessary. They can be mounted using compression fittings or adjustable fixtures as needed.Q: What benefits does mineral insulated construction provide for RTD sensors?

A: The mineral insulation enhances mechanical strength, vibration resistance, and moisture ingress protection. This prolongs sensor life, maintains calibration accuracy, and ensures reliable performance under demanding conditions, reducing downtime and maintenance costs.Q: How is the sensor calibrated and what standards does it meet?

A: Each RTD sensor is calibrated according to international standards IEC 60751 / DIN EN 60751, ensuring Class A or B accuracy as specified. Calibration guarantees each sensor meets rigorous requirements for critical temperature measurement tasks.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

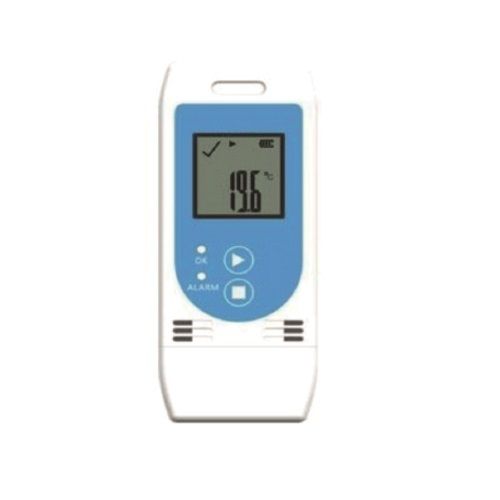

More Products in Data Loggers Category

Multi Use Data logger

Price 1.0 INR / Number

Minimum Order Quantity : 1 Number

Usage : Industrial, Pharmaceutical, Food Storage, Transportation

Wireless : Other, No (USB Download)

Product Type : Multi Use Data Logger

Signal Type : Digital

Single Use Data Logger

Price 1.0 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Industrial

Product Type : Data Logger

Signal Type : Digital

Temperature And Humidity Data Logger

Price 1.0 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Industrial

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS